Just Ordered A Taycan? Here Are Production Facts That Will Blow Your Mind

If you’ve ever been to Zuffenhausen, it is in quite a central urban location, is a major thoroughfare for traffic and sits alongside residential and commercial developments. Not the place for a car factory. But for symbolic reasons, Porsche has chosen to work within its limitations to continue building not just its current models but also its all-electric Taycan, which required a new factory.

If you’ve ever been to Zuffenhausen, you’d realise it’s not what you’d expect of a car factory. It is in quite a central urban location, is a major thoroughfare for traffic and sits alongside residential and commercial developments.

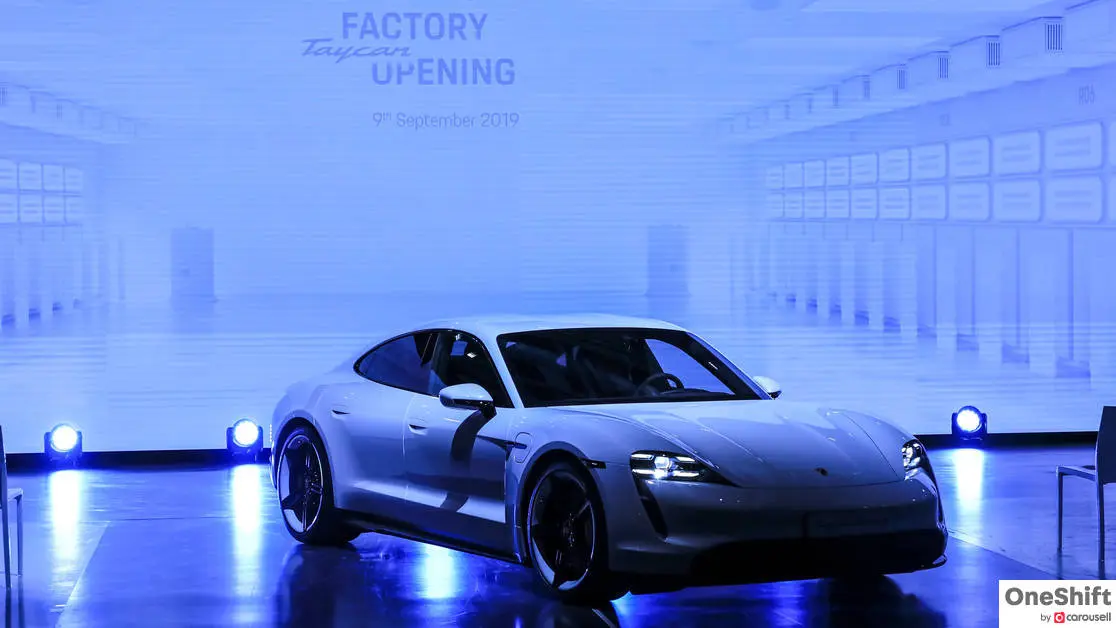

But for symbolic reasons, Porsche has chosen to work within its limitations to continue building not just its current models but also its all-electric Taycan, which required a new factory.

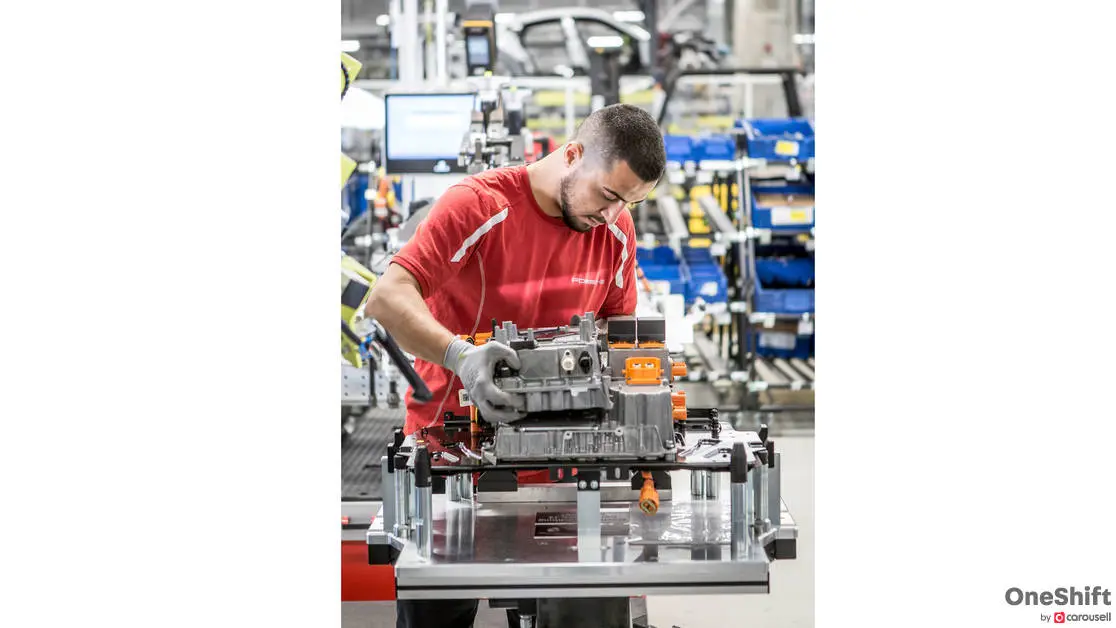

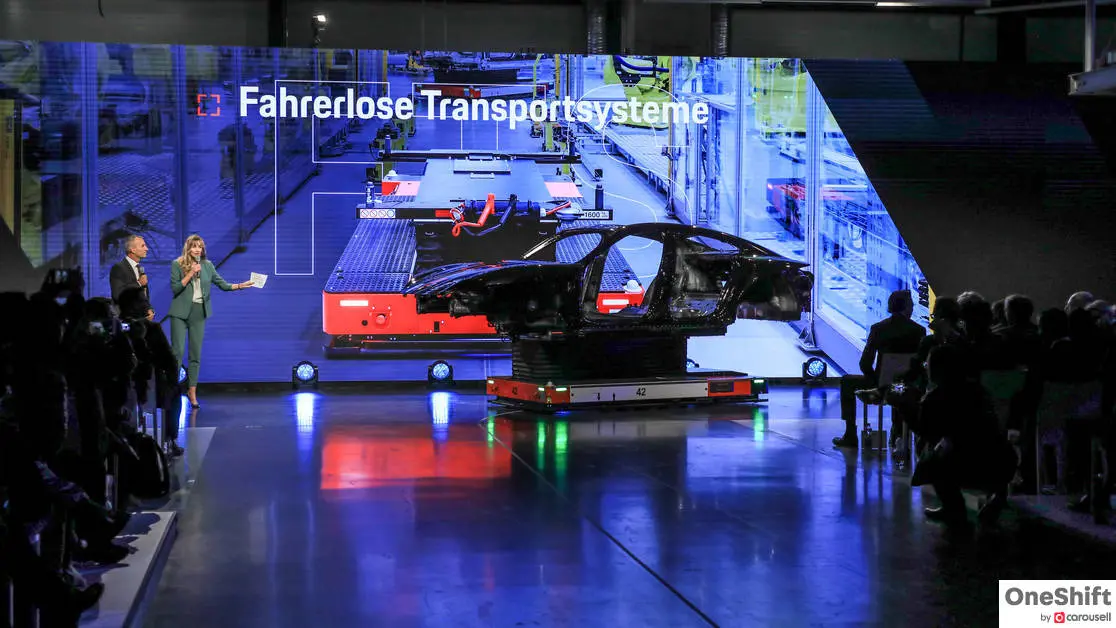

Here are some amazing facts we learnt from a private tour of the Taycan factory:

Credits: Text by James Wong; Photos by Porsche

Get the Best Price for your used car

from 500+ dealers in 24 hours

- Convenient and Hassle-Free

- Consumer Protection

Transparent Process

With No Obligation