We Toured One Of The Most Advanced Car Factories In The World: The Hyundai Motor Group Innovation Centre Singapore

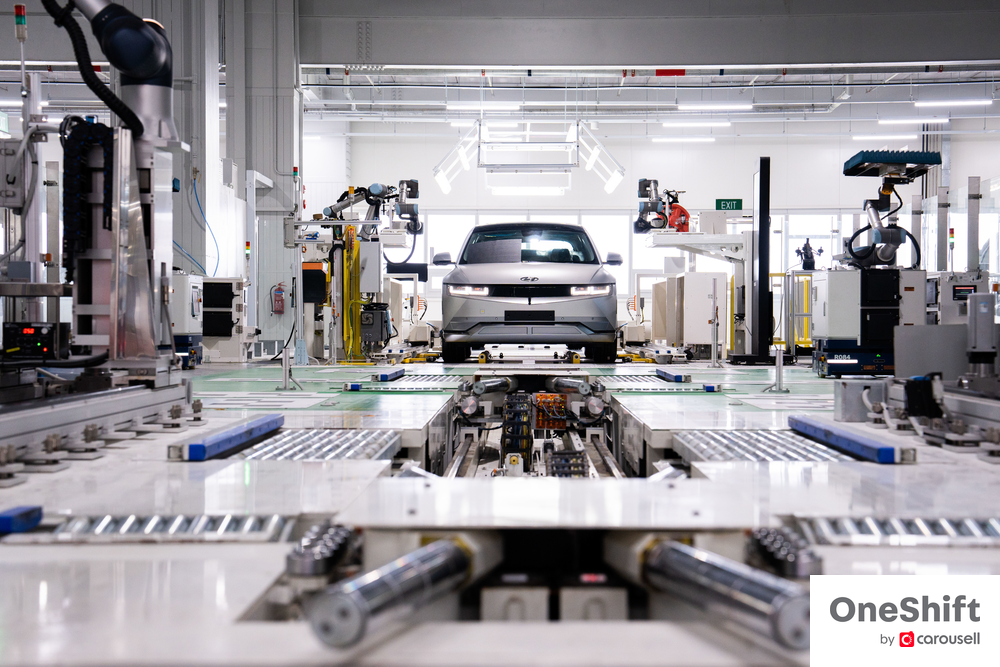

Up to 30,000 EVs per annum can be built at HMGICS.

A car factory in Singapore? We’ve not seen one of those since Ford and Mercedes-Benz in the 1980s, but now we are at the doors of a brand spanking new facility built by Hyundai Motor Group in Bulim at the Jurong Innovation Hub, built to a staggering seven-storey 86,900 m2 space that can manufacture up to 30,000 EVs per annum.

Called the Hyundai Motor Group Innovation Centre in Singapore (HMGICS) - notice that they didn’t call it a factory? - it’s one of two Hyundai’s innovation centres worldwide that will drive the company’s electrification future. The other is in Ulsan, South Korea. That Singapore was the only other place in the world Hyundai chose to spearhead this speaks volumes. But it also befuddles most observers at first glance - how can Singapore be cost-effective enough to do manufacturing - something we’ve moved away from already quite some time ago?

Building cars on a little island? Here’s how

The answer is to reduce the use of labour as much as possible, which forms the highest cost of operating here. Hyundai is quick to point out that there is no production line per se in HMGICS. Instead, in place is a cell-based production model that basically offers total flexibility depending on various demands. And in each cell, there are mostly robots which are controlled only by a few workers. Approximately 50% of all tasks are carried out by 200 robots and they handle more than 60% of component process management, ordering and transportation. The theory is that humans are freed from repetitive and laborious tasks to focus on more creative and productive duties. What’s amazing is that most of these robots are invented in-house by Hyundai.

Indeed, this is probably the most automated manufacturing facility I’ve seen in my life. However, it is not merely automation but also flexibility - melding the two together is no mean feat. In the command centre, there is a huge ‘digital twin’ metaverse replica of the production floor, right down to the position of all of the robots. They are given missions to accomplish here, where tasks are simulated in the virtual world and then robots will physically carry out the tasks in reality. The line between virtual and physical is really blurred.

Efficiency of both robots and humans is also checked at all times to ensure bottlenecks are stamped out. Time and performance are measured for each and every task. In theory, if there was a customer complaint about a fault in a car, there is the ability to trace back to the car’s production to see exactly what went wrong, and when, and why.

To be honest, it feels a little dystopian. But Hyundai assures that the intention is not to keep a watchful eye on its workers but rather to ensure any inefficiencies are dealt with.

Can you share specifically how technology helps the worker at HMGICS?

There is a wearable suit that transforms into a chair when a worker adopts a sitting position. I think many of us might want one of these!

There are also smart glasses that project a screen within one’s line of sight - much like a heads-up display in a car - so a worker doesn’t have to continuously turn his/her head to a monitor.

And how could we forget SPOT - double checking on the undercarriage to make sure everything's alright!

HMGICS is also for the public to enjoy

To be sure, Hyundai has not left out fun from the equation. On top of the multi-million dollar building is a 618-metre rooftop ‘Skytrack’ - essentially a banked oval circuit where every single car manufactured at HMGICS is tested before they’re handed over to their owners. It protrudes 4 metres out from the perimeter of the building, sits 26 metres above ground and has been specifically damped so that it won’t affect the rest of the building structurally even with cars barrelling down the rooftop every day. And to make sure everyone is safe in the event of an accident, the guard rails are also 31.5% stronger than usual!

Members of the public can sign up for test rides here and have the closest thing to a race track experience in Singapore. The last I saw this concept was the FIAT Lingotto factory in Turin. Really cool, I must say, and those 33-degree banked corners are more thrilling than they seem, even with just a 83 km/h speed limit. For those who prefer something more sedate, there is a Virtual Reality (VR) tour of the factory that the public can sign up for.

So… Why are there vegetables growing at HMGICS?

Upon entering HMGICS, one would notice vegetable crops growing within the lobby! Integrated into HMGICS is a sustainable Smart Farm that is almost entirely automated. Perhaps at least partially answering the government’s call for food self-sufficiency - 30% locally produced food by 2030 - the Smart Farm’s nine different produce will be given as a souvenir for visitors and are donated to local communities. Very soon, it will also supply an on-site Korean fusion farm-to-table restaurant that will open its doors in Q2 2024.

Picking up your car from HMGICS? It’s a good idea

Hyundai customers would now have the option to pick up their cars either from Komoco Motors at Leng Kee, or to head down to HMGICS. If they choose the latter, there is a unique handover zone where an introductory video plays on a giant screen, before the IONIQ 5 is brought out by robots into the delivery room, framed by a customisable wallpaper in the background. The robots can rotate the cars and allow them to park closer to each other than any human could, a unique innovation by Hyundai.

The whole delivery sequence feels special, arguably as good as, if not better than what luxury brands offer today.

What else can we expect from HMGICS?

Today, HMGICS produces the IONIQ 5 as well as the fully autonomous IONIQ 5 robotaxi - the latter is exported to the United States. It will soon produce the IONIQ 6 next year, and in the future it will also build Purpose Built Vehicles (PBVs), which are customised cars for certain applications. This is of course made possible due to the immense flexibility afforded by the cell-based production.

It will certainly be interesting to see what HMHICS would be building next. We got a hint that it will be more than just cars. It might be multi-modal forms of transport - think flying cars. Yes, it sounds crazy, but Hyundai thinks it is a very realistic form of transport within our lifetimes.

Hyundai also made it clear that what we saw at HMGICS is merely the baseline of what to expect. It wants to innovate together with Big Tech, start ups and universities to create new technologies - that’s what it’s all about, rather than just a simple car factory.

HMGICS will certainly be cemented in Singapore’s history books as a milestone we will all remember - and the first IONIQ 5 produced will be donated to the National Museum of Singapore to be included into their National Collection. A fitting way to commemorate a new era for Singapore and for Hyundai.

Photos by James Wong and HMGICS

---

Selling your car? Whatever the reason, caryousell@carousell, sell your car at the highest price today.

Get the Best Price for your used car

from 500+ dealers in 24 hours

- Convenient and Hassle-Free

- Consumer Protection

Transparent Process

With No Obligation